Becoming more common in our industry these days, due to our now more common freak weather conditions, is the installation of anti-flood or non-return valves. These valves are generally fitted below ground on an outgoing pipe from a property usually within the last manhole chamber prior to the main sewer.

The valve will shut under pressure should a main sewer surcharge and prevent flooding upstream through the connecting line. Unfortunately, even though London’s sewer system (for example) was over engineered when constructed, and although it has generally stood the test of time, the increase in the load required of it, misuse and our life style changes could not have been anticipated.

Anti-flood valves are by no means a new concept, original valves such as Eureka Trunk valves or Tidal valves were used years ago and many still exist today, although you would struggle to find one that is fully operational.

Eureka Trunk valves are constructed out of cast iron and operate on a rising float to shut a flap, their age and usual lack of maintenance means that these units are now suffering from corrosion and damage rendering them useless. However they are still manufactured and are available today.

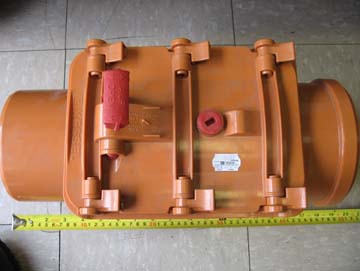

A Forge Anti-Flood valve is a replica of the Eureka valve and has been on the market for some time, these are made of lightweight polypropylene and are more durable and reliable than the cast iron versions. They are easier to fit, maintain and are more economical.

Tidal valves are commonly made of vitrified clay and operate by a copper float rising in a water seal to fit a rubber seating which closes the incoming pipe. These do not corrode to the same extent as cast iron but are similarly rarely maintained and are usually also found non-operational.

Both of these valves can be found fitted to lines entering a main sewer at a low invert level, proving that even years ago main sewers not coping with a heavy load were still a concern. In fact we believe that during the original construction of Joseph Bazalgette’s London Public Sewer system, circa 1860, calculations proved that even the over engineered design would not prevent the risk of flooding in some circumstances. It was accepted that below ground basement areas or pavement vaults could flood at least once a year and as such these areas were kept for storage or access purposes. However, now that we always seem to be outgrowing our available spaces these vaults and basements have been converted to living areas without due consideration to these risks and therefore problems have increased.

Non-return valves can also be fitted to above ground pipework and branches preventing similar situations from occurring in communal stacks and the associated pipework. They can basically be fitted anywhere, as long as there is easy access to them for servicing.

As well as the two mentioned above there are many other types of valves available; Kessel valves, Hunter valves, Capricorn or Redi valves each of which have various advantages and disadvantages. Ranging from size, operational characteristics and required load. We can advise and recommend based on circumstances.

Kessel valves in particular are now becoming more popular and we have fitted several. They have an advantage over the standard non return valves which just shut under a back pressure. Once shut the property’s drainage system is then non operational and therefore flooding can still occur as the system fills during use or rain.

Kessel pumpfix valves have an inbuilt pump. A sensor in the valve detects a back flow of water and shuts the valve, a second sensor can then detect an increasing water level on the upstream part of the valve and once at a certain level the pump will operate and pump surplus water back through the shut valve, removing the build up of water and again preventing flooding. The pumps are quite small, but they are efficient and have a good flow rate and can pump against a head of water in excess of 6m. This pumped water will simply go back into the surcharged sewer system and be distributed along its length to the next available lowest point discharge.

MG Drainage can assist you with anti-flood valve installations to: prevent backflow through drainage systems, sewer surcharging, back-up during heavy rain, property flooding, basement flooding, sewer flooding, back surge prevention, system isolation, flood defence and pump station failure. Prevention of flooding from rivers, brooks, culverts and streams.

We can install and maintain the following types of anti-flood valve / non-return valve; Hunter, Eureka Trunk, Multi-Kwik non-return, Tidal ball interceptor, Kessel, Forge, Redi, Aquaflow, Wavin, Fernco. ACO Junior M back flow gully, ACO ARA in-line automated anti-flood system, ACO SERA in-line passive anti-flood system.

There are many types of valve available, single flap, double flap, stainless steel flap, manual or automatic and the above is just a selection. Anti-flood valves should be chosen specifically to suit each case and requirement and we can advise based on circumstances.